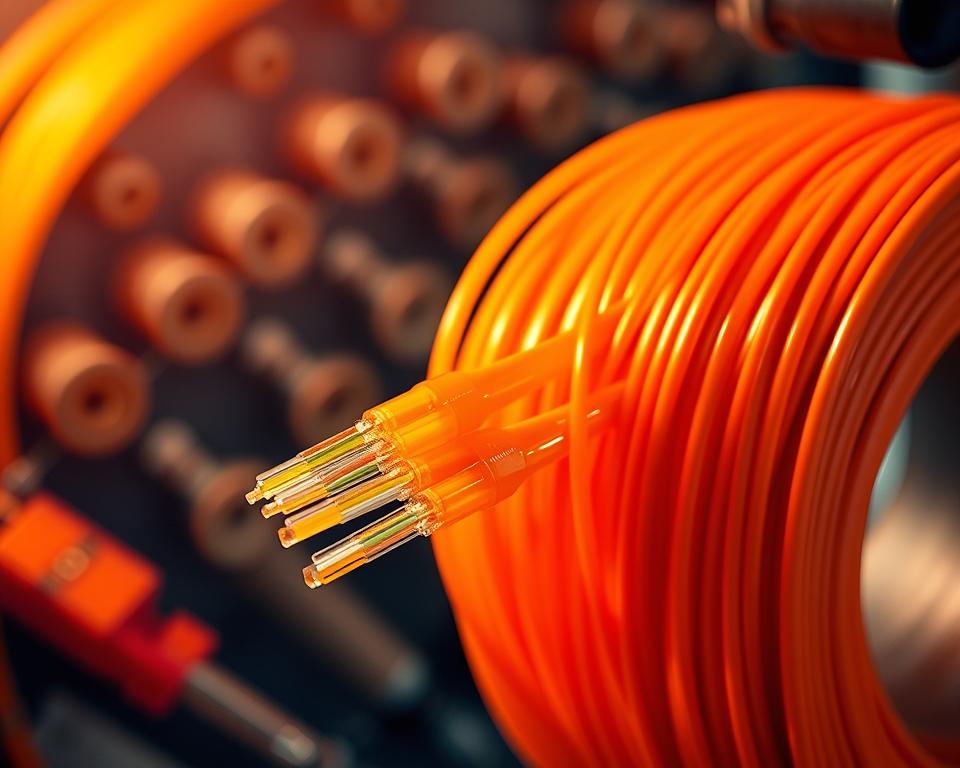

FTTH Wire Manufacturing Line – State-of-the-art Manufacturing System

Were you aware that modern fiber optic wire networks function at velocities of up to 190 m/min? Such remarkable performance results from advanced manufacturing solutions tailored to high-speed output.

These systems are built to handle various cable types, such as drop cables and firmly insulated cables. Their efficient construction, commonly less than twenty-six meters, makes them ideal for contemporary plants.

Integration with smart factory systems secures smooth functioning. Via MES/ERP connectivity, these fiber ribbone line assembly lines provide unparalleled accuracy and productivity. This renders them the leading option for businesses aiming to stay ahead in the telecommunication sector.

Introduction to FTTH Cable Production Line

Streamlined production systems are crucial for meeting the growing need for steadfast connections. Such mechanisms are engineered to produce premium fiber optic cables that drive modern networks. With advanced technology, they guarantee exactness and swiftness in all phases of the production.

Understanding the FTTH Manufacturing Line

The FTTH manufacturing line constitutes a consolidated process for fabricating FTTH drop cables. These cables consist of uncoated strands strengthened by iron or FRP materials, merging with protective sheathing. This produces a durable and efficient solution for fast digital connectivity.

It supports multiple compounds, including PVC, LSZH, and PE polymers. Such adaptability guarantees it satisfies assorted sector requirements. Additionally, the quad-head fiber payout mechanism offers precise tension control, ensuring accuracy within ±0.05N.

Why Choose Our Advanced Manufacturing System?

Our system distinguishes itself for its exactness and productivity. Here’s why it’s a top choice:

- Manages various wire sizes such as 2.0×3.0mm and 2.0×5.0mm drop cables

- Works with LSZH, PVC, and PE covering substances for adaptable uses

- Boasts a quad-head payout mechanism controlling tension between 0.4N and 1.5N

- Achieves speeds reaching 9km/h for 2.0×3.0mm cable outputs

With these features, our machine ensures smooth operations and high-quality output. Thus, it becomes the optimal option for enterprises striving to lead in the optical cable sector.

Highlights of Our FTTH Manufacturing System

Modern manufacturing systems are transforming how fiber wires are made. Our advanced equipment merges exactness, performance, and modern advancements to produce premium performance. The following outlines the remarkable components that position our system at the forefront.

Exact Extrusion Unit with Fine-tuning Head

At the heart of our system is a specialized 50mm extruder designed for precise material distribution. It secures uniform excellence throughout each cable produced. The free adjustment head allows for seamless customization, catering to various materials like PVC, LSZH, and PE resins.

Using OMRON thermal regulation, the system maintains an accuracy of ±1°C. This level of precision guarantees optimal performance and reduces waste, ensuring it is a budget-friendly option for fabricators.

Automated Fiber Dispensing with Strain Management

The automated fiber unwinding unit operates under a controlled tension of 0.4N up to 1.2N. Such regulation facilitates flawless fiber manipulation and diminishes breakage risks. The dual-wheel capstan system, with diameters of 640mm and 400mm, further enhances stability and control.

This aspect is especially advantageous in fabricating premium fiber wires, as it ensures consistent tension throughout the process.

Automated Take-Up and Line-Receiving System

Our dual-shaft take-up system supports reels ranging from PN400 to PN630, ensuring versatility across different production demands. Its self-operating reel collection removes manual intervention, resulting in time efficiency and decreased labor outlay.

Furthermore, an X-type laser-based diameter measuring tool ensures immediate quality verification, confirming that each optical cable adheres to rigorous benchmarks, resulting in trustworthy and long-lasting outputs.

Cutting-edge Innovations Driving Our Manufacturing

Modern innovations are revolutionizing the production of fiber optic cables. Our equipment is engineered to provide exactness, consistency, and productivity, ensuring top-quality results for every project. Let’s delve into the innovative aspects that differentiate our system.

International Industrial Computer Control System

The backbone of our system is the FiberCAN PLC integrated with an industrial computer terminal. This technology ensures seamless operations and real-time monitoring. It permits meticulous modifications, which improve the standard of every optical fiber made.

With a power consumption of just 35KW/h during normal operation, it offers low energy consumption. This reduces operational costs while maintaining high performance. With a 9m spool accumulator, production remains constant, reducing idle time and enhancing performance.

High Stability and Reliability with Famous Brand Components

We utilize top-quality elements from reputed brands like OMRON controllers and worldwide motor suppliers picked for their strength and exactness, which secure enduring performance.

Incorporating reinforced steel wires with cutting-edge FIMT handling processes enhances rigidity and steadiness, ensuring that every optical cable meets industry standards for quality and performance.

MES/ERP Connectivity Integration

Our equipment integrates seamlessly with MES and ERP systems, enabling real-time production tracking. It provides complete visibility and operational efficiency across all stages.

With this integration, businesses can monitor production metrics, optimize workflows, and reduce waste, rendering it a savvy option for today’s industrial plants.

| Feature | Benefit |

|---|---|

| FiberCAN-based Control Module | Accurate control and immediate supervision |

| 35KW/h Operational Energy Use | Energy-efficient operations |

| 9m Cable Accumulator | Seamless operation |

| OMRON-based Control Units | Reliable and exact performance |

| ERP System Compatibility | Instantaneous monitoring |

Uses of the FTTH Manufacturing System

Modern fabrication systems have redefined the process of building trustworthy fiber cables. They are engineered to fulfill varied commercial requirements, ensuring adaptability and accuracy across usages. The following outlines the primary applications of this state-of-the-art system.

Producing FTTH Drop Cables

Our equipment is superb for fabricating drop cables, a cornerstone of fast broadband access. It processes reinforcement strands varying from ø0.4 to ø1.0, securing structural integrity. The central shaft hole diameter of ø56 allows for seamless integration with PN400 pay-off reels.

Important elements consist of:

- Fiber-reinforced polymer with minor steel wire dispensing for extra support

- Portable die backing for rapid setup modifications

- Adaptability to meet interior as well as exterior standards

Producing Both Tight Buffered and Loose Tube Cables

The system is also ideal for producing tight buffered and loose tube cables. Boasting a minimal attenuation of only 0.02dB/km, these cables perform remarkably well. Their careful stranding guarantees exact assembly, and processing ø1.2mm steel wires further enhances durability.

Tailored Options for Diverse Cable Configurations

Versatility characterizes our manufacturing process. It is compatible with an array of materials and setups, thus fitting multiple applications. Regardless of the cable’s intended environment, our system produces stable, high-quality results. This adaptability ensures that businesses can meet specific requirements without compromising on performance.

Advantages of Our FTTH Manufacturing System

Choosing state-of-the-art production solutions offers considerable gains to companies in the fiber optics industry. Such systems streamline processes, lower expenses, and produce premium results. Below, we explore the key benefits that make our equipment a top choice for modern manufacturers.

Improved Operational Speed and Yield

Our machinery operates at high velocity, reaching 7-9km/h outputs as per fiber secondary coating line cable size, allowing businesses to meet growing demands without compromising quality. Its self-operating reel system minimizes human intervention, thus saving time and cutting costs.

Economical Fiber Optic System Implementation

With optimized energy consumption of 35KW/h, our equipment reduces operational costs. A user-friendly design with a 1000mm operational height boosts both comfort and productivity.

Smooth and Reliable Cable Surface

Precision extrusion ensures a smooth and reliable surface for every fiber optic product, thereby reducing attenuation to ≤0.02dB/km for peak performance. Incorporating steel reinforcement further solidifies the cables, adapting them to diverse applications.

| Aspect | Benefit |

|---|---|

| 7-9km/h Output | Increased operational efficiency |

| Efficient Power Usage | Cost savings |

| ≤0.02dB/km Loss | Enhanced signal quality |

| Ergonomic Design Height | User-friendly setup |

Conclusion

Advanced fiber optic manufacturing systems are setting new standards in the industry. With precision engineering and smart integration, these machines deliver unmatched reliability and efficiency. Achieving speeds of up to 190 m/min, they secure substantial ROI for enterprises.

They are complemented by expert technical assistance and tailored configuration choices to suit your requirements. Be it expanding production or boosting quality standards, our system is crafted to keep you at the forefront.

Set to upgrade your manufacturing capabilities? Get in touch to learn about bespoke solutions designed for you. Embrace the next generation of fiber technology through our top-tier systems.